500kg/h solar panel crushing and separation machine project in UK

Because of the rising demand for environmental recycling and the necessity of waste solar panel disposal, more and more businesses invest in recycling solar panel to get precious metals. For example, on 25th February 2025, a customer from the UK inquired about how to setup a 500KG/H physical e-waste recycling plant for waste solar panel disposal. This client told us “..complete line – from disassembling photovoltaic panels to material separation for getting silicon and metals. With capacity 500 kg/h..send me the layout, quotation…” The following are the specific details of our communication in this case:

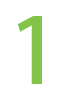

What is the basic equipment of solar panel crushing and separation machine project?

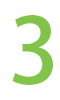

Solar panel frame removal machine

It can remove more than 85% of the glass on the solar panel. At the same time, the equipment is equipped with dust removal equipment. And there is no dust and pollution during the working process.The treated photovoltaic panels are convenient for transportation and further recycling.

This plant includes double shafts shredder, hammer mill, vibrating screening machine, gravity separator, electrostatic separator. They can help you get silicon, metals and plastic.

What is the design of a 500kg/h solar panel crushing and separation line?

When you want to setup an solar panel crushing and separation line, factory area are also two aspects you must consider. Usually, the whole solar panel recycling area is divided into three parts:

How much does it cost to build a solar panel crushing and separation plant in UK?

Finally, the client from the UK inquired about the quotation of the solar panel crushing and separation machine project with a capacity of 500kg/h . Because of quality e-waste recycling equipment use, the price of it is $76,000- $130,000. Can I set up a 500kg/h photovoltaic panels recycling plant in UK at a lower cost?

The answer is yes. You can replace the fully automatic frame removal machine with a semi-automatic frame removing equipment. It has a capacity of 500- 1000 kg/h, which can fully meet your requirement of recycling 500kg/h of waste solar panel. And it has a more economical price.