Silicon Based Photovoltaic Panels Recycling Technology

As the first generations of photovoltaic (PV) modules approach the end of their life cycles, the global solar industry is facing a new challenge: how to recycle millions of tons of retired solar panels, especially silicon-based ones. Silicon-based PV panels account for over 95% of the global market share, making it essential to establish scalable, efficient, and eco-friendly recycling solutions. In this article, we explore the core technologies, processing systems, and top questions that buyers, plant owners, and recyclers typically ask when considering investments in solar panel recycling systems.

Why do you focus on silicon-based PV panels?

Silicon-based PV modules—whether monocrystalline or polycrystalline—contain high-value materials such as:

Key silicon based solar panels recycling method: mechanical vs pyrolysis process

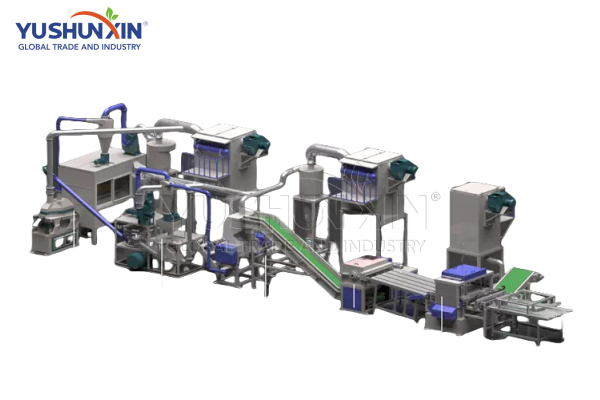

Mechanical recycling technology

This method involves dismantling, crushing, and separating different materials through size reduction, density, conductivity, and vibration.

Pyrolysis recycling technology

Pyrolysis involves heating PV modules in an oxygen-free environment to break down polymers and extract valuable inorganic materials.

Top 5 technical questions asked by customer

ContentHide

- Why do you focus on silicon-based PV panels?

- Key silicon based solar panels recycling method: mechanical vs pyrolysis process

- Top 5 technical questions asked by customer

- What’s the recovery rate and material purityfrom silicon based photovoltaic panels recycling?

- Can your system process all kinds of silicon PV panels?

- Is EVA completely removedfrom silicon based solar panels disposal? Any residuals?

- What about emissions and environmental impactabout recycling silicon based solar panels?

- Investment vs ROI for silicon based solar panels disposal: Is it profitable?