Solar Panels Recycling Process

As solar panels reach the end of their life cycle, efficient recycling becomes essential for environmental sustainability and material recovery. Two primary methods are widely adopted in the industry: the Mechanical Method and the Pyrolysis Method. Each approach involves specific processes and equipment designed to maximize the recovery of valuable materials such as glass, aluminum, copper, and silicon.

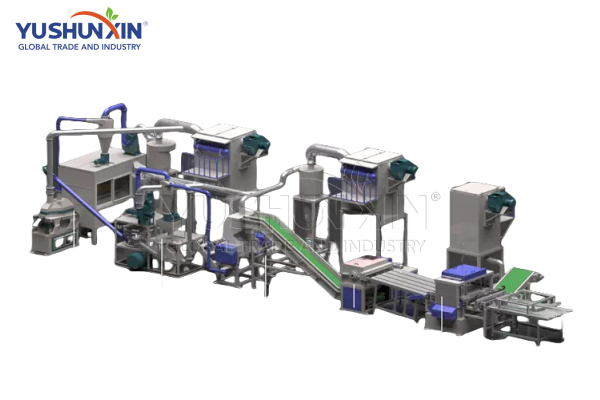

Mechanical Method: Step-by-Step Solar Panel Recycling Equipment Breakdown

The mechanical recycling method focuses on the physical separation of components. It is environmentally friendly, avoids chemical emissions, and is suitable for large-scale operations.

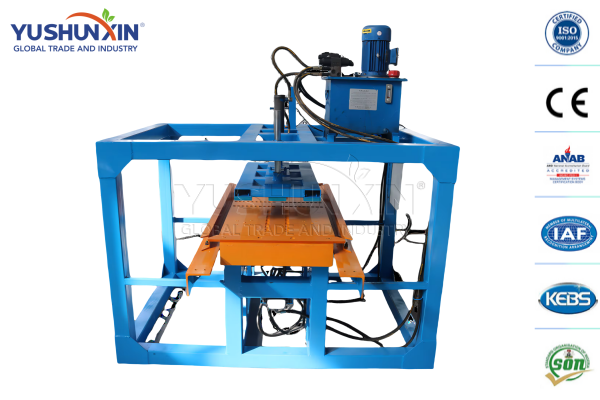

Removing aluminum frame

This machine removes the aluminum frame from the panel automatically. And the aluminum can be recycled and reused directly. For this, the precision of this equipment ensures minimal damage to the remaining structure.

Shredding glass into pieces

The system has 30 heating tubes that soften the EVA glue and separate the glass from the panel surface. And the blade inside the device breaks it into small pieces. Finally, there will be some glass slag and EVA glue left on the back panel. If you need, we will provide a brush to clean the glass residue on the back panel.

Initial shredding of the back plate

Once removing the frame and glass, you can use a double shafts shredder to process the panel into smaller flakes. The typical output size ranges from 30 to 80 mm, preparing the material for finer grinding.

Secondary grinding back plate

The hammer mill further reduces the material size to less than 5 mm, enabling the liberation of metals, polymers, and silicon particles.

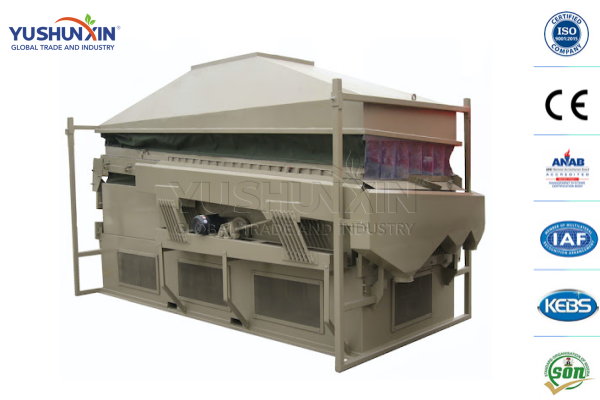

Vibration screening material

We recommend circular vibrating screener in this step. Because, this screener sorts crushed materials based on particle size. At this stage, glass powder, plastic residues, and metallic fragments are separated into different output streams.

Gravity-based separation

Gravity separator, the machine uses the principle of gravity separation to separate heavier particles (such as copper and silicon) from the lighter EVA glue.

Final purification stage

This stage can use electrostatic separator. The final purification stage uses electrostatic principles to separate conductive materials (metallic copper) from non-conductive materials (EVA glue and silicon). This significantly improves the purity of the materials.

Pyrolysis Method: High-Temperature Solar Panels Recycling Technology

The pyrolysis method utilizes thermal decomposition in an oxygen-free environment to break down solar panels into their core materials. And this method is effective for removing encapsulants like EVA and recovering pure silicon wafers.

Comparison: Mechanical vs Pyrolysis Solar Panels Recycling Methods

Each solar panels recycling method offers unique benefits. Below is a detailed comparison to help determine which solution best suits different customer profiles:

| Criteria | Mechanical Method | Pyrolysis Method |

| Budget | Lower initial investment | Higher due to thermal system costs |

| Plant Setup Complexity | Moderate, modular design | Complex, requires thermal control and safety |

| Environmental Permits | Fewer permits required | Requires air emission and thermal process permits |

| Environmental Impact | Minimal emissions | Emissions must be strictly controlled |

| Recycling Efficiency | High for glass and metals | High for silicon and EVA removal |

| Operation Skill Level | Easier to operate and maintain | Requires skilled operators for thermal systems |

| Material Purity | High purity with multi-stage separation | Very high purity, especially for silicon |

| Space Requirement | Compact layout | Larger due to heat insulation and cooling zones |

| Equipment Transportation | Easier due to modular machinery | Requires special handling for pyrolysis unit |

| Suitable For | Small to medium recyclers, pilot plants | Large-scale, industrial recycling operations |

Both the mechanical and pyrolysis methods have proven effective in solar panel recycling, yet they serve different needs. The mechanical method is more accessible, with lower startup costs and easier installation. While the pyrolysis method delivers higher material purity and efficiency, especially for recovering silicon from complex panel structures. For this, when choosing the best solution, consider your budget, production scale, local environmental policies, and end-material requirements.

ContentHide