How to dismantle solar panels for recycling? There are various solar panel dismantling machines for your choice in YUSHUNXIN. In addition, you can setup a solar panel disassembly line, which can help you improve the dismantling quality and speed up the photovoltaic panels recycling. And whether what kind of photovoltaic panel you want to disassemble, it can fully meet your needs. Besides, if you want to expand the production scale later, you only need to replace some key equipment in the whole production line for that of a larger capacity.

Top 2 types of solar panel dismantling machines in YUSHUNXIN

In YUSHUNXIN, there are two types of solar panel dismantling machines for your choice. In terms of dismantling method, it can be divided into frame removal and glass removal.

Solar panel frame removal machine

Semi-automatic frame removal machine

This machine can remove the aluminum frame at the edge of the solar panels. And it needs two workers to run this machine. A worker carries used photovoltaic panels to the equipment for adjustment, while another worker starts the equipment for operation.

For this purpose, we have set up a foot-operated device to start the equipment for easy operation. However, you need to adjust the data on the control cabinet in advance.

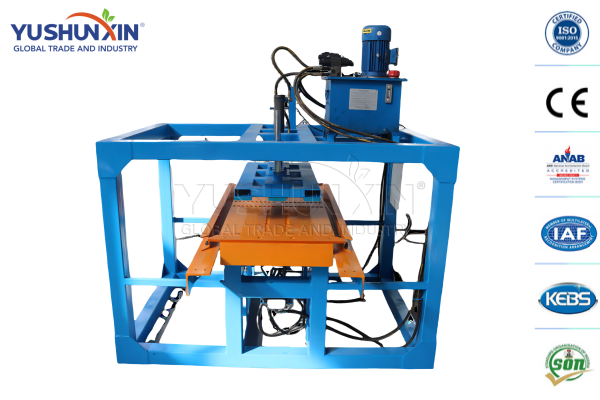

Fully automatic frame removing equipment

Compared with semi-automatic frame removal equipment, its advantage is that it can reduce labor costs. In addition, it has its own conveying device and can directly connect to the next device without a conveyor belt.

More importantly, the disassembly speed of fully automatic frame removing equipment is faster, and it can disassemble a photovoltaic panel in one minute.

Photovoltaic panels glass removing machine

It uses the blades inside to crush the glass into small pieces. The spacing of the blades is adjustable. In addition, there are 30 heating lamps in the glass removing machine to soften the EVA glue on the photovoltaic panel to facilitate the crushing of the glass.

In the process of glass removal, some dust will be generated. For this reason, we have specially equipped a pulse dust collector to deal with dust to maintain the production environment.

How to get more profits after dismantling solar panels?

If you want to further get more profits from solar panels after disassembly, besides the above processes, you also need to process photovoltaic panels after disassembly as follows:

How to buy quality equipment for your solar panel dismantling line?

After deciding your solar panel dismantling plan and equipment, you also need to pay attention to quality solar panel dismantling equipment purchasing. High quality e-waste recycling machines have characteristics of high working efficiency, less impediment, less maintenance cost, etc. But how to buy quality solar panel dismantling machine? There are two tips for you.

How much does it cost to disassemble solar panel?

Is there solar panel disassembly line in Chile?

The answer is yes. And besides photovoltaic panel dismantling in Chile, we also help e-waste managers in many other countries to finish it successfully. Such as US, India, Italy, South Africa, Turkey, etc.