As global solar energy adoption continues to grow, so does the amount of waste solar panels reaching end-of-life. These old photovoltaic (PV) panels contain valuable materials like glass, aluminum, EVA glue layers, and plastic backsheets. But you must separate them efficiently to achieve true recycling value. And one of the most important machines used in this process is the gravity separator, especially in the step that handles crushed mixed materials after shredding. Whether you run a full PV panel recycling plant or are just starting with small-scale processing, this machine can greatly improve separation accuracy and boost your return on investment.

What is a gravity separator for photovoltaic panels disposal?

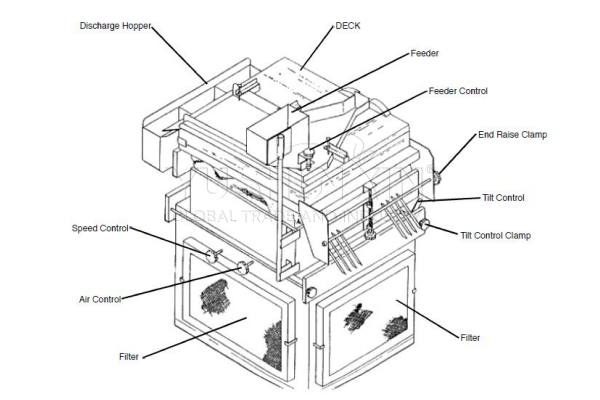

A gravity separator is a machine that separates materials based on their weight and density.

Simply put, it helps you sort out light and heavy pieces from a mixed batch of crushed materials. In the photovoltaic panel recycling process, after the panels are crushed into small pieces, you get a mixture of glass, plastic backsheets, and EVA glue layers. These materials are all mixed together. This is where the gravity separator comes in — it helps separate them cleanly and automatically.

How does gravity separator work to sieve for solar panels disposal?

Generally speaking, collecting dust and exhaust is essential in the whole process of solar panel disposal. However, in fact, you need to collect at the three stages. They are dismantling stage, crushing&separating stage, and pyrolysis stage. Why?

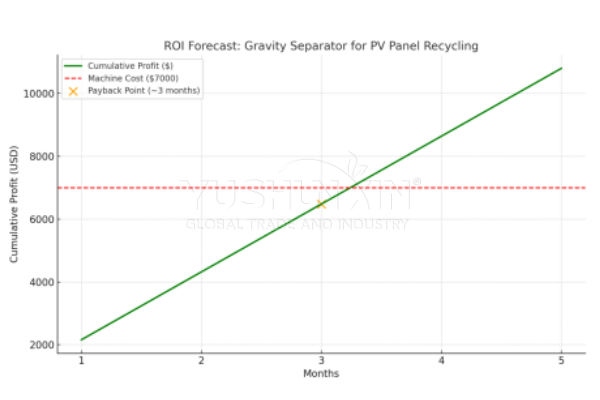

How fast can you recover the investment about gravity separation machine?

One of the most common questions from our clients is: “How soon can I make my money back after buying the gravity separator?” The answer depends on the amount of PV waste you process daily and the market value of separated materials like plastic backsheets. Let’s break it down:

ContentHide