Dust collection is vital in solar panel recycling, capturing dust and toxic fumes from dismantling, crushing, and pyrolysis. Our tailored system ensures clean air, protects workers, meets environmental standards, and suits both mechanical and thermal processes. So, investing in high-efficiency dust collectors supports safe, responsible, and efficient recycling of waste solar panels into valuable resources.

When need to collect dust and exhaust during solar panel recycling process?

Generally speaking, collecting dust and exhaust is essential in the whole process of solar panel disposal. However, in fact, you need to collect at the three stages. They are dismantling stage, crushing&separating stage, and pyrolysis stage. Why?

During mechanical dismantling

Dismantling is the first step in photovoltaic panel recycling. In this process, components such as the aluminum frame, glass, and junction box are separated from the panel body. While this step seems simple, it can generate fine dust, especially glass particles and EVA flakes, which may become airborne.

If not collected in time, these particles may spread across the workshop and pose health risks to workers. So, it is recommended to install localized dust extraction units and a cyclone dust collector to remove large-sized particulate matter efficiently at this stage.

Crushing and screening stage

Crushing and screening are essential to liberate valuable materials such as silicon, silver, and copper. However, this stage produces the most dust. And the crushed glass and silicon fragments can be extremely fine, often smaller than 10μm, and pose significant respiratory risks.

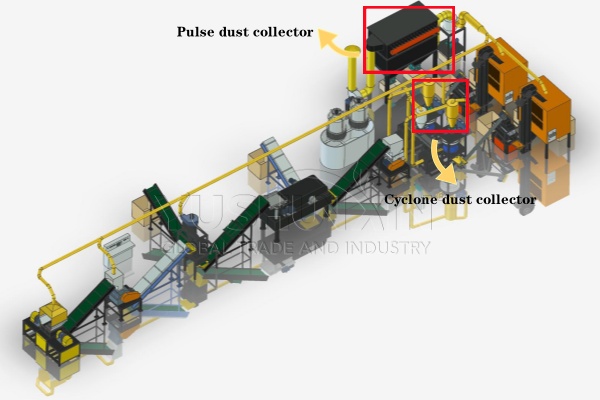

So, a two-stage dust collector system is typically required here—starting with a cyclone separator followed by a high-efficiency pulse filter. This ensures that over 99.5% of the dust particles can be captured, keeping the working environment safe and clean.

During pyrolysis stage

In thermal treatment, especially pyrolysis, the EVA encapsulant is decomposed under high temperatures. And this process releases not only fine particulate matter but also harmful gases such as VOCs, HF, and HCl. These emissions must be strictly controlled to meet environmental regulations.

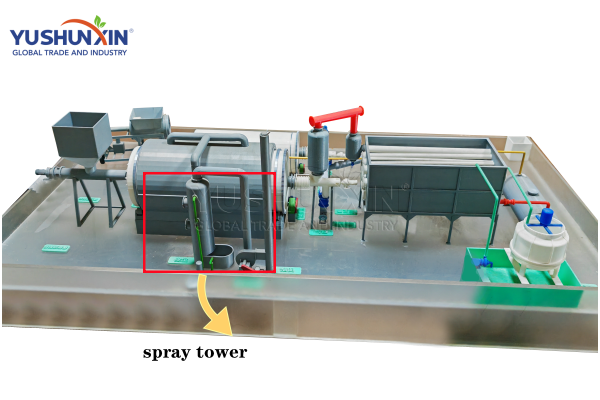

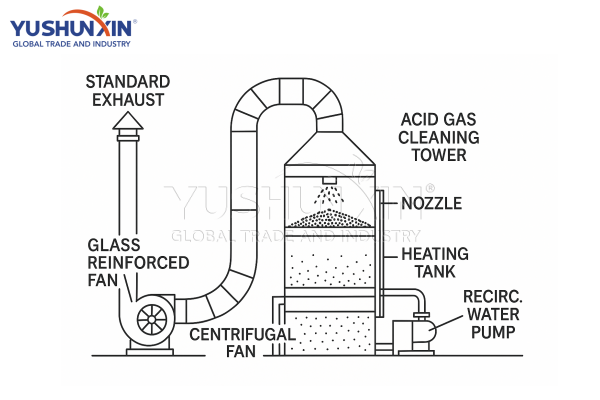

A spray tower is commonly used to neutralize acidic gases, followed by an activated carbon filter to absorb VOCs and odors. For this, these systems ensure that both air pollution and odor complaints are minimized.

What equipment is needed in dust collector system for solar panels disposal?

According to the above information, the dust collector system in solar panel recycling contains 3 parts. That is: dust removal during dismantling, crushing & screening, and pyrolysis. Different working conditions produce different types and concentrations of dust and gases, so we recommend matching professional equipment accordingly.

Dust collection during mechanical method

Cyclone dust collector for initial dust control ——dismantling stage

When dismantling photovoltaic panels mechanically, especially when removing the aluminum frame and glass cover, a considerable amount of glass powder and EVA film fragments may be released. Although this dust is not very fine, it spreads easily and may accumulate on work surfaces or be inhaled by operators. So, to solve this, we suggest installing a cyclone dust collector near the dismantling station.

This device uses centrifugal force to separate larger dust particles from the air efficiently. And it is simple to maintain and especially suitable for collecting medium-to-large particles like broken glass and aluminum flakes. Furthermore, the average collection efficiency can reach 85%-90%, and it’s often the first stage in a multi-level dust removal line.

Pulse filter + cyclone separator for high efficiency dust capture ——crushing & separating stage

Crushing and screening are the most dust-intensive steps in the mechanical recycling method. As panels are crushed to release silicon, copper, and other materials, they generate large volumes of fine particles—many less than 10 microns in diameter.

➡ To deal with this, we recommend a two-stage dust collection system:

This combination not only improves overall efficiency but also prolongs equipment lifespan. And it is especially useful when processing 500–1000kg/h of crushed solar panels continuously.

Dust collection during mechanical method

Spray tower and activated carbon box for toxic gas removal ——pyrolysis stage

During pyrolysis of solar panels (for example, to decompose EVA layers at 450–550°C), not only dust but also toxic gases such as HF, HCl, VOCs are released. These emissions pose serious risks to both the environment and workers’ health.

This two-stage gas purification setup helps your factory stay compliant with environmental regulations and eliminates odor complaints from nearby residents.

What is the cost of dust collector system for solar panels disposal?

After deciding what equipment is used in your dust collector system, it is time to purchase it for your solar panel recycling line.

If you need other machines for solar panels processing, YUSHUNXIN also can fully meet your requirements. Such as dismantling machine, gravity separator, electrostatic separator, vibrating screen machine, etc. Welcome to tell us all you requirements for solar panels disposal now!

ContentHide