How to Dismantle Solar Panels for Recycling in Chile

On 10th March 2024, we received factory visit customers from Chile, who inquired about how to dismantle solar panels for recycling. The client told us “In order to ensure the integrity of the photovoltaic panel aluminum frame disassembly and the quality of the glass, what equipment is most suitable?” Finally, the customer buy solar panel dismantling machines with two machines. The following are the specific details of communication in this case:

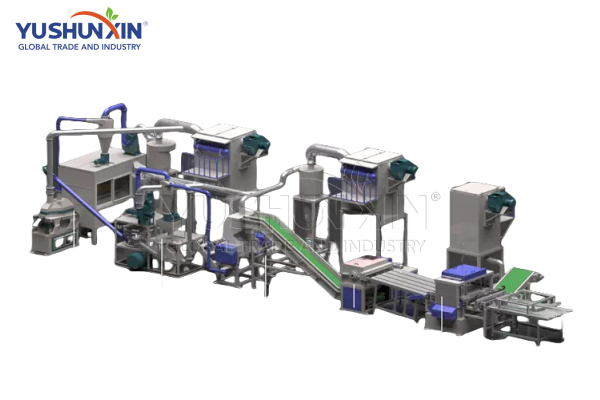

What machines are suitable for dismantling solar panels?

Frame removal equipment

It uses heating, vibration, pressure or other technical means to weaken the bonding layer between the glass and the back sheet (usually plastic or polyester material) of the photovoltaic panel, thereby separating the glass from other components. And the deglazing machine usually has multiple functions such as heating, precise temperature control, and pressure control to ensure that the glass is not broken during the disassembly process and to ensure efficient and safe disassembly.

How does disassembly accuracy affect the recycling rate of solar panels?

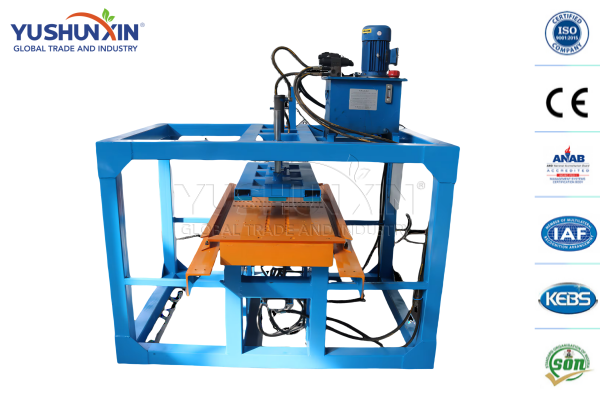

Ensure the integrity of the aluminum frame——frame removal machine

Temperature and pressure control——glass removing machine

After explaining to the American customer the relationship between disassembly accuracy and equipment, we told him that our equipment can achieve the disassembly effect he wants in the above manner.