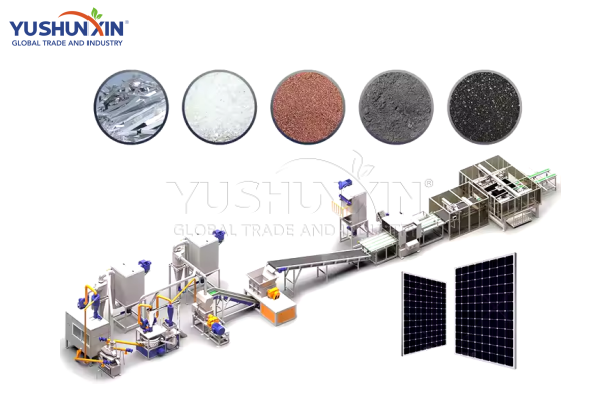

Are you finding machines for 1000kg/h photovoltaic panels recycling machine? YUSHUNXIN can offer you customized machine proposal, from dismantling to separation for silicon, plastic and metals recycling. Then, for pyrolysis method, there are 3 types of plants for your choice. As reliable provider for solar panel recycling solutions and equipment, YUSHUNXIN can also design the 1000kg/h photovoltaic panels recycling machine proposal according to your budget. Welcome to contact us for your own photovoltaic panels recycling plan now.

What is the common process of 1000kg/h photovoltaic panels recycling machine proposal?

In order to make mechanical photovoltaic panels recycling line operate smoothly to make profits for you, suitable equipment is necessary. For this, capacity is an item you must focus on. With different output of solar panels recycling, you need to buy correspond machines. In general, for 1000kg/h photovoltaic panels recycling machine proposal, it is advisable to use machines from dismantling to separating as follows:

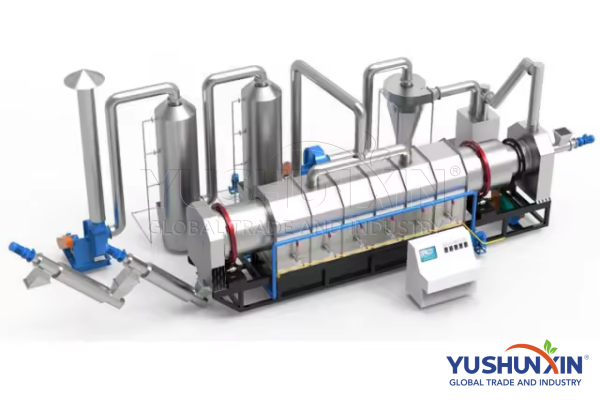

Which pyrolysis furnace is the best for your 1000kg/h photovoltaic panels recycling line?

As mentioned above, pyrolysis method is also the key to recycle solar panels. But there are three pyrolysis machines, which one is suitable for your 1000kg/h photovoltaic panels recycling line? Our engineers have tips for you.

Batch type pyrolysis machine

This is the most basic type of pyrolysis furnace, suitable for small and medium-sized production lines. So it is suitable for customers with limited equipment investment budget and low requirements for processing efficiency. The capacity is about 100-500 kg/h. And there are three heating methods to choose from: gas, oil, and electricity.

Semi-automatic pyrolysis furnace

The semi-automatic pyrolysis equipment has been partially upgraded on the basis of the batch type, realizing automatic feeding or slag discharge. Its production capacity is 500-800 kg/h, which is suitable for medium-sized photovoltaic panel recycling projects and a continuous production cycle of 8-16 hours.

And it can reduce some manual operations and improve efficiency. Furthermore, the secondary combustion device is used to improve the heat utilization rate.

Fully automatic pyrolysis equipment

The fully automatic pyrolysis equipment is the most advanced pyrolysis system at present, with continuous feeding, continuous slag discharge and intelligent temperature control system. The production capacity can be customized to fully meet or even exceed the 1000kg/h requirement.

Therefore, it is particularly suitable for large-scale photovoltaic module recycling plants. It can achieve 24-hour uninterrupted production and save labor costs. And it is also equipped with exhaust gas purification and tail gas combustion systems to meet environmental protection standards.

➡ So, according to your 1000kg/h capacity requirement, fully automatic pyrolysis equipment is the best choice for you.

How much does it cost to buy a 1000kg/h photovoltaic panels recycling machine?

ContentHide